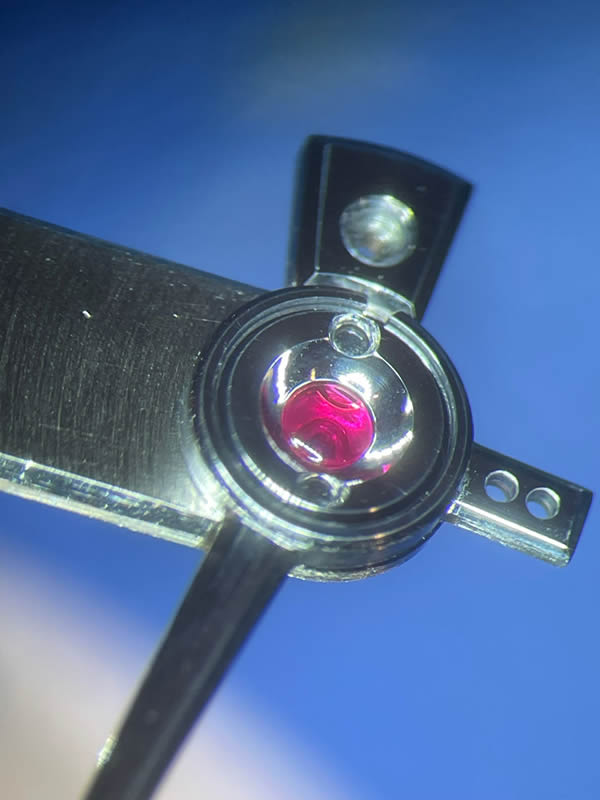

[Pipe]

The pipe is made up of complex configurations, and it is not easy to cut it beautifully even with modern CNC machines. The sides and even the invisible backside is polished and finished until all traces of machine work have disappeared.

These processes, including the final polishing and finishing, are delicate operations in which chamfering and polishing are performed while checking with a microscope, and if the tool is applied incorrectly even for a moment, it can never be corrected, so the work requires continuous concentration.

[Hand]

At supplier GMG Composants in Le Locle, Mr. Sekiguchi himself hand-crafts everything from shaping to polishing, cutting from solid 18K white gold and 18K rose gold.